TracNav menu

The Long Tail of Information Exchanges

Today we have a number of methods of exchanging information on capital projects:

- CAD drawing exchange

- Product model exchange (STEP)

- Dictionary exchange based on Part 4

- Semantic data exchange based on Part 2

We are just starting to see tools that will enable semantic data exchange in a production environment, but the first three are mature and used routinely today. Which should you use?

The answer is, if the problem looks like a nail use a hammer; if the problem looks like a screw use a screwdriver.

For instance, there is more than one CAD system in wide use today. On a large project it is unusual that all the players use the same one. Sometimes all an engineer needs is to open with his own CAD system a drawing authored with a different one. If that is genuinely what is needed, a CAD translation tool is what he should use.

Similarly, in a manufacturing environment it is unlikely that all of the players, each with a different part to play, will use the same software. In this case the use of ISO 10303 AP 203/214, which captures all of the information in the product model, is the kind of thing that should be used to exchange information.

Coming into the capital projects industry, if what you really want to do is to convert, say, a 3D plant model, authored with one 3D engineering system, to a different one, a dictionary exchange based on Part 4 is a good solution.

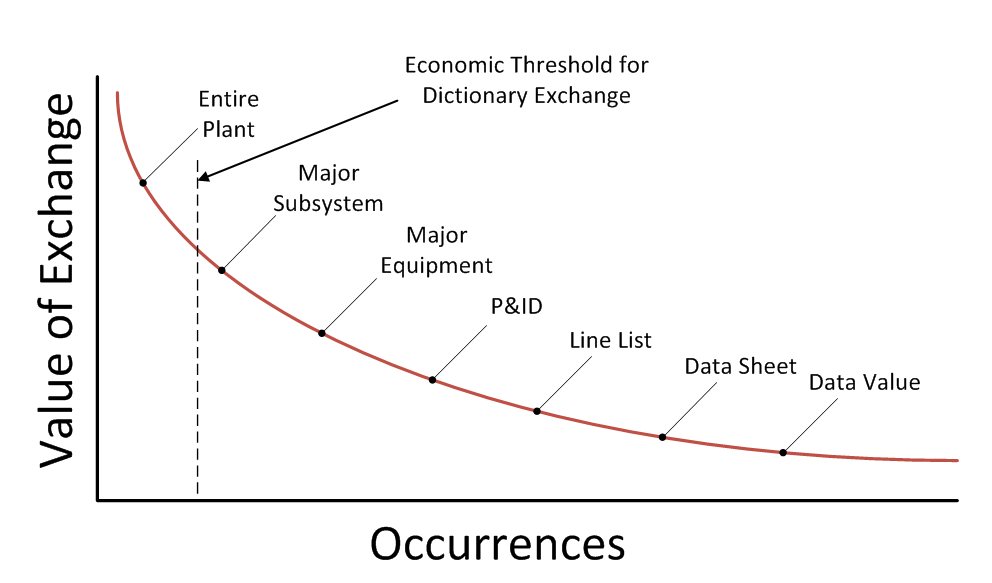

However, on a large capital project there are a great many information exchanges that are not individually high enough value to warrant the brute force approach of database mapping inherent in a purely dictionary-based exchange. To borrow an idea from a book by Chris Anderson, there is a "Long Tail" in information exchange.

The diagram shows a continuum from large exchanges, where a typical request is to translate an entire plant from one 3D engineering system to another, all the way to individual data values on a data sheet. In each exchange, what we really want is something like a magic "ISO 15926" button. (After all, the design is done; the translating seems to be just mechanics.) But since we don't have such a magic button our only choice is to rekey the information (or, more likely, muddle through without it.)

At the tail end these exchanges are too small, and too different from each other, to justify the data mapping exercise that would be required with a dictionary-based exchange. But on a large capital project, with many engineers filling out data sheets, this kind of exchange happens thousands of times every day. In mathematical terms, the area under the curve is immense. Taken together they represent a large opportunity to increase efficiency and reliability.

Next

Attachments

-

ISO15926Primer_19_LongTail_a.png

(35.8 kB) - added by gordonrachar

12 years ago.

The Long Tail